由于石油供應越來越緊張,甲醇、乙醇來替代汽油燃燒�,柴油車用菜籽油、葵花油等植物油做燃料可能在所難免�。

甲醇和乙醇

取代汽油供發(fā)動機試用的技術已經(jīng)進行20多年了,幾乎是成熟的替代燃料.我相信各大汽車生產(chǎn)公司都準備好了甲醇或乙醇汽車的技術.然而植物油

取代柴油的研究工作方興未艾。

澳大利亞,德國,意大利,美國已經(jīng)制定了有關質量標準�����。柴油機植物油燃料主要成分是單烷基脂肪酸酯�����。

要保證發(fā)動機能很好地"消化"植物油,

必須對植物油進行加工�����。轉換單,雙,三甘油酰酯化合物為甲基酯油是最基本的過程����,其中水分�����,游離脂肪酸,游離甘油和總甘油

(包括游離甘油和單,雙,三甘油酰酯化合物) ,殘留醇<LLA4812-OH>(影響閃點)等成分也需要控制

����,因為這些成分有可能使油品在儲藏過程中變質,也會導致很多發(fā)動機工作問題�����,例如發(fā)動機中沉積物增加等�����。

北斗星儀器向您提供整套在線檢測分析設備,歡迎研發(fā)單位,設計單位和直接用戶咨詢���。

電話:010-82640226

傳真:010-82640221

酯化率分析儀器�����,酯化反應轉化率分析儀器,轉酯化反應轉化率分析儀器,酯交換反應轉化率分析儀器,烷基酯化反應轉化率分析儀器,生物柴油酯化轉化率分析儀器,酯化反應平均酯化度分析儀器,轉酯化反應平均酯化度分析儀器,酯交換反應平均酯化度分析儀器,烷基酯化反應平均酯化度分析儀器,生物柴油酯化平均酯化度分析儀器,酯化反應酯化率分析儀器,轉酯化反應酯化率分析儀器,酯交換反應酯化率分析儀器,烷基酯化反應酯化率分析儀器,生物柴油酯化酯化率分析儀器,

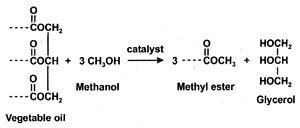

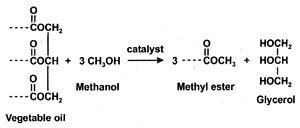

Biodiesel, defined as the monoalkyl esters of fatty acids from vegetable

oils and animal fats (1), neat and blended with conventional diesel fuel has

significant potential as alternative diesel fuel (2, 3). Initial stages of

commercialization have been successful. Biodiesel is usually obtained from

the neat vegetable oil by transesterification with an alcohol, usually

methanol, in presence of a catalyst, usually a base such as KOH (Fig. 1).

Glycerol is a by-product of the reaction. Other possible materials in

biodiesel include residual alcohol, moisture, unreacted feedstock (triacylglycerides),

incompletely reacted mono- and diglycerides, and free fatty acids.

Fuel standards have been developed in Austria (ÖNORM C 1190), Germany (DIN

51606) and Italy (UNI 10635:1997), and in the United States a provisional

ASTM (American Society for Testing and Materials) standard has been

completed. The fuel standards address quality issues of biodiesel by

limiting materials such as free and total glycerol (total glycerol is the

sum of free glycerol and glycerol bound as mono-, di-, and triacylglycerides),

water (moisture), free fatty acid (by limiting the acid number), and

residual alcohol (by limiting the flash point). These materials need to be

limited in biodiesel because their presence can lead to fuel deterioration

during storage as well as to significant operational problems such as engine

deposits. The rationale for various quality test methods in biodiesel

standards (United States, Austria) has been discussed (4, 5).

The analysis of biodiesel for various contaminants is usually conducted

by gas chromatography (GC). Originally, a method for analyzing mono-, di-,

and triacylglycerides together with methyl esters in one run was developed

(6). This method was extended to include glycerol (7). Other papers also

report on the GC analysis of biodiesel for determining contaminants such as

methanol, glycerol, and glycerides (8-13). Biodiesel was also analyzed by GC

for minor components such as sterols (14, 15). Preseparation of biodiesel

and its contaminants by high-performance liquid chromatography (HPLC) prior

to GC was reported (16). However, other methods have been utilized in the

analysis of biodiesel, including HPLC with density detection (17) or pulsed

amperometric detection for determining glycerol (18), and viscosity (19).

Fig. 1. Transesterification reaction. |

On the other hand, spectroscopic methods are being increasingly utilized for

quality control purposes. Near-infrared (NIR) spectroscopy is among the

methods finding increased use. Operational ease, rapidity of measurement,

and nondestructiveness are among the chief reasons for this development

besides accuracy and reliability. NIR spectroscopy is now being used

routinely for analyzing the fatty acid composition of oilseeds besides

finding other applications in the field of fats and oils (20, 21). To the

best of our knowledge, the NIR spectra of numerous fatty compounds were

first reported more than 40 years ago (22). Several other papers discuss NIR

spectra of long-chain compounds (23-25). Here we report differences in the

NIR spectra of vegetable oils (soybean oil used as example here) and their

methyl esters as well as initial results on the potential use of these

spectral differences to monitor progress and endpoint of the

transesterification. A model system consisting of defined concentrations of

contaminants in biodiesel was used. By induction, biodiesel fuel quality can

be assessed. NIR can be an alternative not only to GC but to other methods

in biodiesel standards, for example flash point. Testing biodiesel for every

such specification in the standard is a lengthy and extremely expensive

process. A method such as NIR can shorten this process and render it

considerably less expensive. Spectra were obtained with the aid of a

fiber-optic probe, which makes the use of NIR spectroscopy particularly

easy.

生物柴油技術,動物脂/生物油/植物油轉換柴油發(fā)動機燃料的酯化反應,甲基大豆酯柴油機燃料油生產(chǎn)過程分析儀.豆油分析儀,豆油中甲醇分析儀,豆油中脂肪酸分析儀,豆油中甲基豆油酯分析儀,豆油中丙三醇分析儀,豆油中甘油分析儀,豆油甲基酯中丙三醇分析儀,豆油甲基酯中甘油分析儀,豆油甲基酯中脂肪酸分析儀,甲基酯油水分檢測,游離脂肪酸檢測,游離甘油檢測,總甘油檢測,單甘油酰酯化合物檢測,雙甘油酰酯化合物檢測,三甘油酰酯化合物檢測,殘留醇檢測,甲基酯油水分測定,游離脂肪酸測定,游離甘油測定,總甘油測定,單甘油酰酯化合物測定,雙甘油酰酯化合物測定,三甘油酰酯化合物測定,殘留醇測定,甲基酯油水分分析儀器,游離脂肪酸分析儀器,游離甘油分析儀器,總甘油分析儀器,單甘油酰酯化合物分析儀器,雙甘油酰酯化合物分析儀器,三甘油酰酯化合物分析儀器,殘留醇分析儀器,

生物柴油技術,動物脂/生物油/植物油轉換柴油發(fā)動機燃料的酯化反應,甲基大豆酯柴油機燃料油生產(chǎn)過程分析儀.豆油分析儀,豆油中甲醇分析儀,豆油中脂肪酸分析儀,豆油中甲基豆油酯分析儀,豆油中丙三醇分析儀,豆油中甘油分析儀,豆油甲基酯中丙三醇分析儀,豆油甲基酯中甘油分析儀,豆油甲基酯中脂肪酸分析儀,甲基酯油水分檢測,游離脂肪酸檢測,游離甘油檢測,總甘油檢測,單甘油酰酯化合物檢測,雙甘油酰酯化合物檢測,三甘油酰酯化合物檢測,殘留醇檢測,甲基酯油水分測定,游離脂肪酸測定,游離甘油測定,總甘油測定,單甘油酰酯化合物測定,雙甘油酰酯化合物測定,三甘油酰酯化合物測定,殘留醇測定,甲基酯油水分分析儀器,游離脂肪酸分析儀器,游離甘油分析儀器,總甘油分析儀器,單甘油酰酯化合物分析儀器,雙甘油酰酯化合物分析儀器,三甘油酰酯化合物分析儀器,殘留醇分析儀器,